There are a multitude of rubber materials available for part selection. Of them, EPDM has earned its place as a go-to solution for a variety of reasons.

EPDM is a synthetic rubber common in HVAC, automotive, and several other types of applications. From gaskets to tubing, EPDM is a versatile, cost-effective material. Want to learn more about this material and its benefits? Read on to find more information about this particular polymer and where it’s able to provide value.

What Does EPDM Stand For?

EPDM, also known as Ethylene Propylene Diene Monomer, is a synthetic rubber derived from the polymerization of ethylene, propylene, and certain other alpha-olefin comonomers. The first example of EPDM dates back to Nobel Prize winner Karl Ziegler.

The German scientist discovered that he could product a strong, flexible compound while conducting polymerization experiments. The new material was first introduced to the U.S. market in the early ‘60s, quickly gaining popularity in the roofing and other industries for it’s beneficial properties and cost-effective price point.

One of the major reasons why EPDM caught on as a rubber compound was because it marked the first elastomer developed that combined good heat resistance, ozone resistance, excellent mechanical properties over a wide temperature range, and good chemical stability. While other materials have been created to address greater temperature needs and other performance factors, EPDM has maintained popularity and is ideal for many uses.

Why Do Businesses Use EPDM?

EPDM offers a variety of advantageous properties that make it an all-around quality compound, especially for applications that require a durable material with various resistances. Let’s break down some key advantages of using this material.

Weathering resistance

If you need excellent durability in outdoor conditions, EPDM is a great option. EPDM is able to withstand exposure to the elements, meaning it won’t degrade nearly as quickly as less formidable compounds. These weathering resistances include:

- Outdoor aging

- Ozone

- Sunlight

- Moisture and steam

- General dirt and debris

General durability

EPDM is able to withstand more than just weather. Parts made with EPDM benefit from solid abrasion and tear resistance. The material also has a longer lifespan than some other rubber or plastics, allowing businesses to save money in the long run on replacement parts.

Heat resistance

While it’s not designed for use in environments with extreme temperatures, EPDM does have a fairly wide operating temperature range. Parts made with this material can thrive in environments as cold as -20 to -60 degrees Fahrenheit while also withstanding temperatures up to 350 degrees. Other compounds like silicone may be needed for more extreme heat, but EPDM is still a very stable option when heat is a potential concern.

Acidity resistance

EPDM is an extremely durable material, even when it comes to encountering corrosive substances. Parts made with EPDM are much more resistant to highly acidic substances. This feature is a major benefit for drain hoses and other applications that encounter intermittent or even regular exposure to caustic elements.

Non-toxic and low odor

Unlike some other compounds, EPDM is has low toxicity levels that make it a safe option for applications where contact with the rubber is possible. Also, when adequately formulated, EPDM does not have a strong odor. These features make this type of rubber a valued option for panel seals, window seals, or other parts that people may touch.

Manufacturing process flexibility

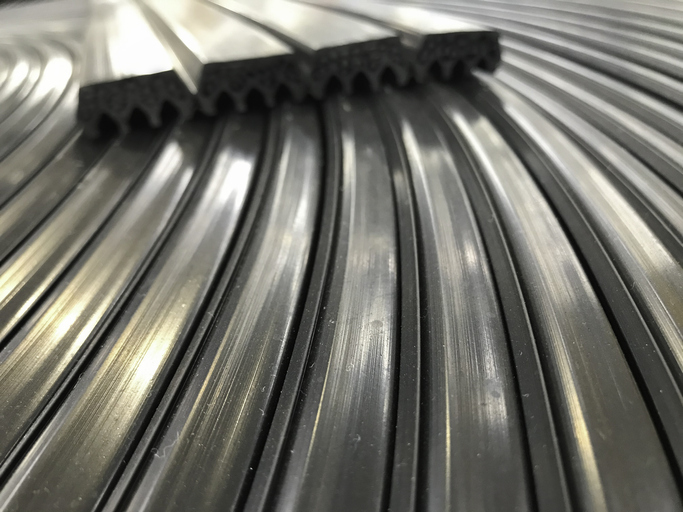

For all it’s benefits, EPDM is incredibly flexible in terms of manufacturing options. This compound can be fabricated in multiple ways, including custom molding, extruding, sheeting, and die cutting. EPDM can also be formed into a variety of densities, such as sponge EPDM, shaped tubes that can bend and fold, and highly dense parts.

Low electrical conductivity

EPDM is an excellent electrical insulator, which allows its use in various applications involving electrical components. It can also withstand high voltage without losing its properties, all while assisting with safety measures.

Are There Situations Where EPDM isn’t a Good Fit?

While EPDM offers a variety of benefits, there are some occasions where EPDM isn’t the right option. The following situations are examples where you’ll likely want to utilize a different material.

Solvent and oil resistance

While EPDM is excellent for use in acidic environments, fuel, oil, and solvents pose problems for this particular material. EPDM is also vulnerable to chemical damage, so it likely isn’t suitable for use in settings where oils and solvents are present.

Specialty situations

EPDM is an incredibly versatile material, but it does have its limitations. Applications with particularly challenging environments or performance needs may call for compounds built for specific requirements. For example, Viton is better served for environments that call for extreme durability. EPDM can do a lot, but there are always times where it’s best to invest in a more specialized material.

What is EPDM Used For?

As you’d expect for such a versatile material, there are several industries and applications that can benefit from EPDM. It’s very common to see EPDM parts used in multiple industries, including HVAC, automotive, and roofing. As for the exact parts, there are numerous options. These include, but are not limited to:

- Seals

- Gaskets

- Grommets

- Tubing

- Spacers

- Shock mounts

- Isolators

- Spacers

- Belts

- Covers

- Brake systems

- Hoses

Bottom-line – EPDM is a Versatile Rubber Material

When you need a rubber material for various parts, odds are that EPDM is a potential option. Since its creation more than half a century ago, this type of rubber has grown into a popular choice thanks to it’s overall benefits, flexibility, and cost-effectiveness compared to other compounds.

EPDM parts play a pivotal role for applications, which is why Timco Rubber partners with businesses to supply them with the parts they need for success. Our experts have supplied businesses with custom rubber and plastic parts for as long as EPDM has been around, and we can work directly with you to provide the perfect parts for your performance needs and budget.

Ready to invest in quality rubber parts? Give us a call at 800-969-6242 or contact us online to talk to one of our experts or get a quote for your project.