Rigid & Flexible PVC Tubing Supplier

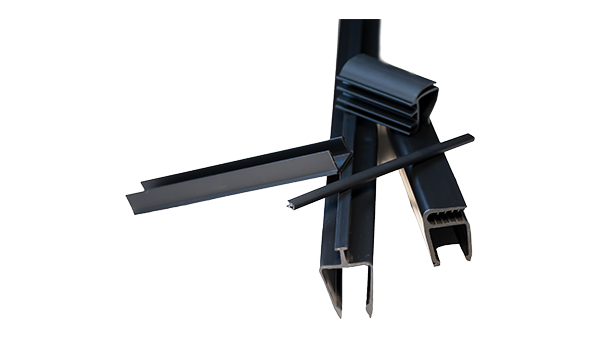

PVC rubber is a strong, lightweight, and durable material that’s ideal for a variety of applications. Timco Rubber custom designs and provides both rigid and flexible PVC products for companies in need of high-quality parts for their applications.

PVC Plastic: A Material for Strong, Lightweight Parts

PVC comes in two basic forms: rigid PVC (also known as uPVC or RPVC) and flexible (soft) PVC. Both rigid and flexible PVC are cost-effective solutions that can be combined with a broad range of additives to enhance performance versatility. Thanks to a wide hardness range, good resistances, and other PVC properties, this material is an appealing option for everything from rigid PVC pipe to clear PVC tubing used in automotive and medical applications.

Whether you need a hard or soft PVC material, Timco can work with you to design custom PVC parts for your exact needs. Our team works with you to identify and provide the best, most cost-effective part solutions for your applications. We can also modify these parts to suit your exact needs, including custom cut PVC pipe, specially graded materials, or some other value-add for your business.

What is PVC?

PVC (polyvinyl chloride) is a thermoplastic material that can be melted repeatedly at certain temperatures and will harden upon cooling. This process makes PVC strong, lightweight, and durable. These qualities make PVC an ideal material for a variety of applications.

While PVC is now a popular material for a variety of applications, its initial discovery was a bit of an accident. German chemist Eugen Baumann first synthesized PVC after numerous experiments. Baumann bottled some vinyl chloride and left it on a shelf. Weeks later, that vinyl chloride had turned into a white solid that is now known as PVC.

These days, PVC has a less accident-based production process. PVC is manufactured by extracting resources from salt and hydrocarbon to produce both chlorine and ethylene. These two substances combine into a vinyl chloride monomer that is polymerized into PVC. From there, PVC can be blended with other formulas to create various formulations based on the desired physical properties of your PVC products.

PVC Properties

- Common Names: Polyvinyl Chloride (PVC)

- Temperature Range

- Low Temperature Usage: -40 degrees C | 5 degrees C

- High Temperature Usage: 60°C | 140°F

- Tensile Strength

- Tensile Strength: 2.60 N/mm2

- Elongation: 100-400%

- Notched Impact Strength: 2.0-45 Kj/m2

- Thermal Coefficient of expansion: 80 x 10-6

- Density 1.38 g/cm3

- Durometer (Hardness) – 15-70 Shore D

- Resistances

- Flame Resistance: Very Good

- UV Resistance: Excellent

- Ozone Resistance: Excellent

- Dilute Acid: Very Good

- Dilute Alkalis: Very Good

- Oils and Greases: Good (variable)

- Aliphatic Hydrocarbons: Very Good

- Halogenated Hydrocarbons: Moderate (variable)

- Alcohols: Good (variable)

- Aromatic Hydrocarbons: Poor

PVC Applications

Rigid (uPVC, RPVC) Applications

Construction

- Rigid PVC tubing for pipes and drains

- Window and door frames

- Clear OD/ID tubing for gas furnaces

Flexible PVC Applications

Electrical

- Coated wire and cable insulation

Automotive

- Protective strips

- Moldings

- Seat coverings

- Interior door panels and pockets

- Seals

Medical

- Surgical equipment

- Pharmaceuticals

- IV bags

- Administrative sets

- Medical packaging

PVC Benefits and Advantages

- Easy to process and blend into both rigid and soft PVC materials.

- It is an extremely lightweight material without sacrificing durability, making it excellent for weight reduction.

- Resistant to grease, oil, and chemicals makes it effective for use in the automotive and medical industries.

- Resistant to bad weather conditions – does not corrode and is very durable over long-term use and exposure.

- Flame resistant with fire prevention properties – difficult to ignite, and without a powerful external flame, will not continue to burn.

- Compatible with a variety of additives – allows PVC to be clear or colored, rigid or flexible.

- Manufacturers can accommodate a variety of performance or design specifications with special additives.

- Excellent electrical insulation properties – ideal for use in cables and other electrical industry applications.

- Offers the combination of being a low-maintenance material with a long lifespan.

Timco: Your Go-To Supplier of Rigid and Flexible PVC Parts

PVC is a versatile material, but supplying the right rigid or flexible part depends on your specific design needs and budget. PVC can be formulated and manufactured in many different ways, which is why Timco works closely with businesses to provide them with custom PVC parts tailored specifically for their applications.

Timco has partnered with businesses to deliver high quality parts and customer service since 1956. Our experts do more than just supply parts – we conduct a comprehensive engineering review to analyze your needs and deliver a custom-designed part solution that addresses all your needs. We also aim to add value at all stages of the process, as we offer several services to help your business save valuable time and money:

- Subassembly of rubber parts

- Kanban replenishment

- Kit assembly

- Flexible control methods

- Our in-house stocking program and on-time delivery

Interested in custom PVC parts for your application?

Call 1-888-754-5136 to find out more, or get a quote on PVC seals, tubing, and other parts.

Not sure which material you need for your custom rubber product? View our rubber material selection guide to learn more about which compound is right for your part needs.