Sponge & Foam Rubber Manufacturer

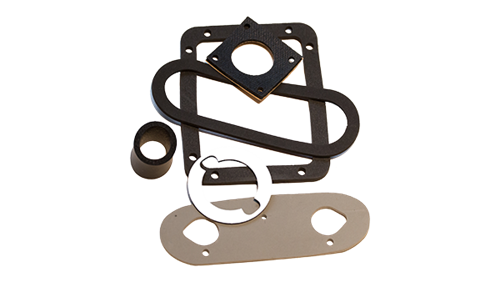

Seals, Tubing & Gaskets & More

Whether you call it foam rubber or sponge rubber, it's important to get the perfect parts for your applications. Timco Rubber works with companies to provides them with custom rubber products that offer cost-effective sealing and cushioning solutions for your applications.

Custom Foam & Sponge Rubber Solutions for Your Business

While the terms foam and sponge are used interchangeably, they aren’t quite the same material. Both foam and sponge have cellular structures, but each option has various features that may make one a better choice for your needs.

A major difference between the two is the open and closed structures of the two materials. Flexible foam rubber (also known as cellular or expanded rubber) has an open cell structure and can be produced in low and high densities, making it ideal for seals and insulation for cabinet and commercial applications. Sponge rubber has a much more closed cell structure that provides strong compression set resistance and compression recovery, along with the ability to block liquids and gases.

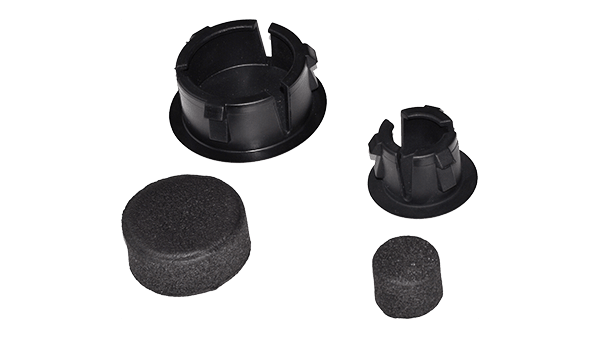

No matter whether you need EPDM foam rubber tubing or sponge rubber vibration isolators, Timco can work with your business to customize a part solution based on your specific needs and budget.

Types of Foam Rubber

Cross-Linked Polyethylene Foam

- Compact

- Water-resistant

- Offers cushioning and support

- More resistance and spring back

Polyurethane Foam

- Lightweight

- Easy to work with

- More cost-effective than other foam options on the market

Microcellular Urethane Foam

- Low compression set

- Excellent durability

- Resistant to abrasion

- Good for open and close applications with repetitive access

Foam Applications

- Dust seals for HVAC access doors

- Foam rubber insulation

- Noise and vibration reducers

- Transportation

- Automotive trim

- Refrigerated transport vehicles

- Foam rubber tubes

- Foam rubber seals

Foam Benefits and Advantages

- Lightweight materials

- Buoyant

- A range of compressibility available

- Excellent cushioning and impact deadening performance

- Thermal and acoustical insulation

- Cost effective compared to other materials

- Can be produce in low and high densities

Types of Sponge Rubber

EPDM Sponge Rubber

- Excellent resisting aging from weather and sunlight

- Withstands adverse outdoor conditions better than neoprene

- Requires proper additive to meet UL flame ratings

- Vulnerable to oils and fuels

Silicone Sponge Rubber

- High temperature stability

- Temperature usage exposure from -100°F up to 500°F

- Strong levels of resilience

- Less flame resistant, usually can't achieve flame ratings beyond UL94HB

- Resists degradation and aging due to sunlight and ozone exposure

PVC/Nitrile Sponge Rubber

- Great thermal conductivity

- Excellent oil and fluid resistance

- Excellent for shock absorption and padding

- Provides gas and air impermeability

Sponge Rubber Applications

- HVAC Market

- Sound and vibration insulation

- Seals for doors, cabinets, etc.

- HVAC & Automotive Markets

- Sound dampening

- Sponge gaskets

- Fabricating processes available for all materials include:

- Die cutting

- Slitting to width

- Adhesive lamination

Sponge Benefits & Advantages

- Highly effective sealing capabilities

- Can be specified in low, medium or high-density firmness

- Controlled compression and recovery characteristics

- Shock absorption attributes

Interested in foam rubber and sponge rubber parts?

Call 1-888-754-5136 to find out more, or get a quote.

Not sure which material you need for your custom rubber product? View our rubber material selection guide.