When vibration is an issue, the right material can make all the difference. Vibration mounts, isolators, and other damping parts can be made with a variety of materials, but it’s essential to find the best, most cost-effective compound for your applications.

Of course, it’s not easy to figure out which material is right for your parts if your not a material expert. Rubber is naturally quite good at dampening vibration, but there are a wide range of different compounds available. Let’s break down what impacts your options and how to choose the best vibration damping materials for your needs.

Ideal Characteristics for Vibration Dampening Materials

Before you can determine which material is best suited for your vibration damping needs, it’s important to consider what you need your parts to do. There are a variety of factors that impact how well your part can deaden vibration, but some applications may favor one characteristic over another. Those factors include:

- Durometer

- Required resistances

- Part size and weight

- Adhesion to metal

Durometer

Determining the right durometer is arguably the most important factor when investing in any parts that will dampen vibration. Any materials used in your parts will need to accommodate the right hardness so that your isolators or other parts aren’t too soft or too stiff. As such, you’ll need to test various materials (and even different formulations of those materials) to achieve the best durometer to dampen any unwanted vibration and sound.

Required resistances

Your operating environment also plays a major role in dictating which materials are right for your parts. Simply put, you need your parts to not only survive, but thrive under different conditions.

Exposure to the outdoors is one such challenge. Any parts that are exposed to the elements will need to resist weathering, ozone exposure, water, and other elemental factors. Other dampeners may be exposed to oil or other substances that can break down some materials over time. Finally, it's always best practice to consider temperature range if your parts will be subjected to hot or cold environments.

Part size and weight

The overall design of the part also impacts material selection and manufacturing. For example, some grommets and isolators will need enough rubber to withstand any pressure coming from the application itself. Other parts may need to be a certain size and weight to properly dampen vibration and noise – too much or too little weight and the parts either won’t work or make the situation worse.

The best way to determine which materials are best is through testing. While you may be able to narrow your selection down to certain materials with an ideal durometer and weight range. This process will help ensure that your parts are right and help you determine the most cost-effective solution to absorb vibrations for your applications.

Adhesion to metal

Simply put, vibration dampeners aren’t going to work if they fall off of your applications. Whether you’re mounting your isolator to a compression or a pipe, these anti-vibration tools need to stay put and do their job. In the case of extreme vibration energy or tricky surfaces, it might be best to opt for higher-quality materials bond better to metal inserts.

Best Material Options for Vibration Damping

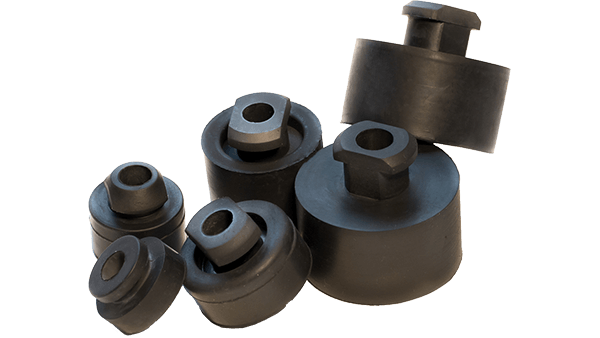

When it comes to vibration isolation, there are a few different go-to rubber materials that will make sense for the vast majority of applications.

- EPDM

- Natural rubber

- Neoprene

EPDM

EPDM rubber is an extremely tough, versatile part that is very resistant to weathering and heat. This particular synthetic material can be formulated in a variety of ways, which offers a lot a variety in terms of weight and durometer and adhesion to metal.

Natural rubber

If you need a part that combines vibration damping with high tensile and tear strength, natural rubber is an intriguing option. Natural rubber can take a beating for a long time – just don’t expect it to hold up well in outdoor conditions or oil resistance.

Neoprene

Neoprene is a multipurpose elastomer that shines in two key situations for vibration damping – oil resistance and adhesion to metal. While a more expensive material than EPDM and other compounds, it’s ability to resist exposure to oil and ability to hold onto metal surfaces and inserts can be worth the cost in order to limit part failure.

Invest in the Best Materials for Your Vibration Damping Applications

When vibration can’t be an issue, it’s important to get your parts right. The good news is that Timco is here to help you determine the best, most cost-effective vibration damping materials for your applications.

Timco works directly with you to identify your exact pain points so that we can design and supply parts made for your needs. Give us a call at 800-969-6242 or contact us online to talk to one of our experts about the parts you need.